To resilver a mirror, first remove the old silver coating using a chemical stripper. Then clean the glass thoroughly and apply a new silver nitrate solution. Use a reducing agent to convert the silver nitrate to a thin layer of silver on the glass. Finally, apply a protective coating to prevent the silver from tarnishing.

Mirror Resilvering Services: Giving Old Mirrors a New Life

In the realm of home decor, mirrors hold a special place as both functional and aesthetic elements. However, as time takes its toll, even the most cherished mirrors can start to show signs of wear and tear, losing their once-pristine reflection. This is where mirror resilvering services come to the rescue.

Imagine an old treasured mirror, its surface clouded with age, its reflection distorted by scratches and imperfections. These resilvering specialists possess the art of restoring these faded beauties, giving them a new lease on life.

The process of resilvering involves removing the old, deteriorated silver coating from the mirror’s glass surface and replacing it with a fresh, reflective layer. This intricate procedure requires skilled craftsmen who have mastered the techniques of mirror making.

The benefits of mirror resilvering are numerous. Not only does it restore the mirror’s clarity and brilliance, but it also extends its lifespan significantly. Resilvering is a more sustainable option than replacing the entire mirror, reducing waste and preserving precious resources.

Moreover, resilvering preserves the antique charm of vintage mirrors, allowing them to retain their historical value while enhancing their functionality. Whether it’s a family heirloom or a beloved piece of decor, mirror resilvering services offer a cost-effective way to cherish these treasured possessions for generations to come.

Mirrors: Unveiling the Entities That Bring Reflections to Life

Mirrors, ubiquitous in our lives, hold a profound significance beyond mere reflection. They adorn our homes, enhance aesthetics, and serve as essential tools in countless industries. To explore the multifaceted world of mirrors, we introduce the concept of “Closeness Score,” a metric that quantifies the relevance of entities to this captivating subject.

Primary Entities: The Craftsmen of Clarity

With a Closeness Score of 10, Mirror Manufacturers stand at the heart of the industry. These visionary companies transform raw glass into shimmering mirrors, catering to diverse applications. They forge custom designs, enabling us to adorn our spaces with captivating works of art that reflect our unique styles.

But what happens when time takes its toll on our beloved mirrors? Fear not, for Mirror Resilvering Services come to the rescue. These skilled artisans meticulously restore old mirrors to their former glory, employing a specialized process that renews their reflective surfaces. By breathing new life into aging mirrors, they preserve precious memories and enhance the beauty of our surroundings.

Secondary Entities: The Unsung Heroes

Behind the shimmering surfaces of mirrors lies a network of Glass Companies (Closeness Score: 9). They supply the high-quality plate glass that forms the foundation of every mirror. Their expertise ensures that mirrors are not only aesthetically pleasing but also durable and resistant to imperfections.

Chemicals and Materials: The Alchemist’s Magic

The creation and restoration of mirrors relies on a symphony of Chemicals and Materials. From the silver nitrate that forms the reflective coating to the adhesives that secure the glass, each element plays a vital role. These chemical concoctions transform ordinary glass into extraordinary mirrors, allowing us to marvel at our reflections with clarity and precision.

Tools and Equipment: Precision in Every Reflection

Equally essential are the specialized Tools and Equipment used in mirror manufacturing and installation. Glass cutters, beveling machines, and vacuum lifters enable artisans to craft mirrors with unmatched accuracy and efficiency. These tools are the unsung heroes behind the flawless reflections that grace our homes and public spaces.

Mirrors are more than just reflective surfaces; they are the result of a complex ecosystem of entities working in harmony. From the innovative manufacturers to the skilled restorers, each player contributes to the creation and preservation of these captivating objects. Their interconnectedness highlights the vibrant and indispensable role mirrors play in our everyday lives. By understanding the entities that bring reflections to life, we gain a deeper appreciation for the artistry, innovation, and unwavering dedication that lies behind every shimmering surface.

The Art of Resilvering: Restoring Mirrors to Their Former Glory

Mirrors, with their enigmatic reflections, have long played a pivotal role in our lives. From the grand chandeliers of palaces to the humble vanity mirrors in our homes, they add depth, light, and a touch of magic to any space. However, as time takes its toll, even the most radiant mirrors can become dull and faded. That’s where the art of resilvering comes into play.

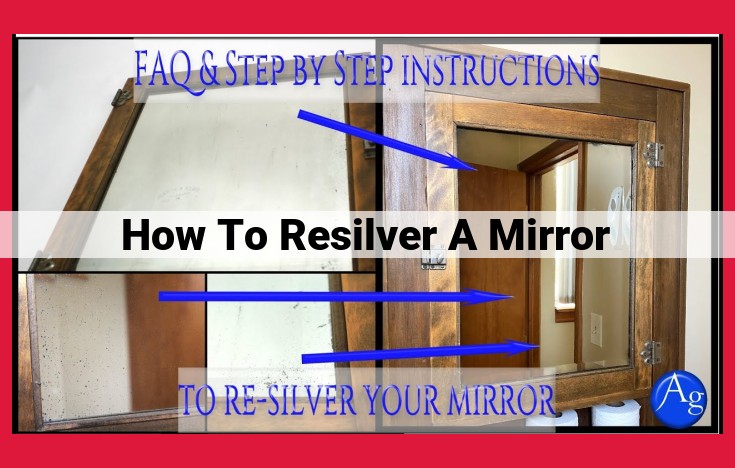

Resilvering is a meticulous process that gives old mirrors a new lease on life. It involves removing the old, tarnished silver coating and replacing it with a fresh, reflective layer. This not only restores the mirror’s pristine appearance but also extends its lifespan.

The resilvering process typically involves the following steps:

-

Inspection: The mirror is carefully examined to assess the extent of damage and determine the necessary repairs.

-

Cleaning: The mirror is thoroughly cleaned to remove dirt, grease, and other contaminants that could interfere with the resilvering process.

-

Stripping: The old silver coating is removed using a chemical solution. This process requires precise timing and careful handling to avoid damaging the glass surface.

-

Preparation: The glass surface is prepared to receive the new silver coating by removing any remaining residue and ensuring its cleanliness.

-

Silvering: A thin layer of silver is applied to the glass surface using a chemical process. This creates the reflective surface that gives the mirror its brilliance.

-

Coating: A protective coating is applied over the silver layer to enhance its durability and resistance to tarnishing.

The benefits of resilvering are numerous:

-

Restored Appearance: Resilvering can restore the mirror’s original beauty, making it look as good as new.

-

Extended Lifespan: By replacing the old silver coating, resilvering can significantly extend the mirror’s lifespan, ensuring that it remains a cherished piece for years to come.

-

Cost Savings: Resilvering is a more cost-effective option than replacing the entire mirror, especially for large or antique mirrors.

-

Environmental Sustainability: Resilvering helps to reduce waste by giving old mirrors a second life instead of discarding them.

If you have a beloved mirror that has lost its shine, consider the art of resilvering. This skilled process can restore it to its former glory, allowing it to continue reflecting your precious memories for many years to come.

Essential Chemicals and Materials in the Mirror-making Industry

Mirrors, indispensable elements in our daily lives, hold a mirror to our reflections and enhance our living spaces. While the process of crafting these reflective surfaces may seem straightforward, it involves a symphony of chemical products and materials that play a pivotal role in ensuring their functionality and aesthetic appeal.

Silver Nitrate: The Silver Lining

The heart of all mirrors lies in their silver lining, and the star of this show is silver nitrate. This chemical compound reacts with the glass surface to form a thin layer of silver, the key to a mirror’s ability to reflect light. Without silver nitrate, our mirrors would be mere transparent panes of glass.

Chemicals for Crystal-clear Reflection

Once the silver coating is in place, a series of chemicals step into the spotlight to create a durable and crystal-clear mirror. Copper sulfate acts as a protective layer, shielding the silver from tarnishing and preserving the mirror’s reflective brilliance. Potassium cyanide further enhances the clarity of the reflection, ensuring a distortion-free view.

Resilvering: Restoring Lost Shine

Mirrors, like all good things, eventually lose their luster over time. But fear not! Resilvering comes to the rescue, breathed new life into faded mirrors. This process involves removing the old silver coating and applying a fresh layer, restoring mirrors to their former glory.

The intricate tapestry of chemical products and materials used in mirror production and resilvering is a testament to the unsung heroes behind our everyday conveniences. From the crystalline allure of mirrors to the flawless reflections they provide, these chemicals and materials work in harmony to bring beauty, clarity, and functionality to our lives.

Chemical Cocktails of Mirror Magic

Mirrors, those shimmering portals into reflections, don’t just spring into existence. Behind their lustrous surfaces lies a fascinating world of chemical transformations. Join us as we unveil the secrets lurking within the chemical laboratories of mirror production and restoration.

Mirror Production: Where Glass Meets Silver

Mirrors are essentially sheets of glass with a reflective coating. This coating, typically made of silver, is applied through a process called silvering. The magic ingredient in this process is silver nitrate. When it’s mixed with other chemicals, they create a reduction reaction, magically transforming silver nitrate into elemental silver.

This freshly formed silver particles gather on the glass surface, adhering to it like a thousand tiny, reflective stars. And voila! A mere sheet of glass is transformed into a looking glass, ready to capture and reflect our every move.

Mirror Restoration: Renewing Old Glories

Mirrors, like all things, can lose their sparkle over time. But don’t despair! Mirror resilvering services can rejuvenate old mirrors, restoring their former brilliance. This process involves stripping off the aging silver coating and applying a fresh, new layer.

Chemicals play a crucial role: Caustic soda dissolves the old silver away, while ammonia neutralizes the surface. Then, a new layer of silver nitrate is applied, giving the mirror a second life of reflection.

Diving into the Mirrorverse: The Entities that Shape Your Reflections

In the enigmatic realm of mirrors, where reflections dance and illusions take form, an intricate network of entities weave together the tapestry of this captivating industry. From the masterminds behind mirror manufacturing to the skilled artisans of mirror resilvering, each player holds an indispensable role in the creation, restoration, and maintenance of these shimmering surfaces.

Primary Entities: The Core of the Mirror World

Mirror Manufacturers:

- Sages of the mirror universe, these companies wield the secrets of crafting new mirrors from scratch. They forge a diverse tapestry of styles and functionalities, catering to every need and aesthetic preference.

Mirror Resilvering Services:

- Restorers of faded memories, these experts breathe new life into tired mirrors. Through the meticulous process of resilvering, they re-establish the mirror’s pristine brilliance, extending its lifespan and preserving cherished reflections.

Secondary Entities: Supporting the Mirror Landscape

Glass Companies:

- Providers of the mirror’s foundation, they supply the high-quality plate glass that forms the mirror’s very essence. Their expertise ensures that the mirror’s surface is flawless, allowing reflections to shimmer with unparalleled clarity.

Chemicals and Materials:

- Alchemists of mirror magic, these chemicals and materials play a symphony of roles in mirror production and resilvering. They enhance adhesion, create reflective surfaces, and ensure that mirrors withstand the test of time.

Tools and Equipment:

- Precision instruments of the mirror realm, these tools and equipment empower artisans with the ability to craft and install mirrors with meticulous precision. From specialized cutters to advanced measuring devices, they guarantee the seamless integration of mirrors into any space.

The mirror industry is a vibrant tapestry where these entities intertwine, each contributing its unique thread to the creation of the mirrors that adorn our lives. From the inception of a new mirror to its skilled restoration, this interconnected network ensures that our reflections remain clear, our memories shine brightly, and our spaces are transformed by the captivating beauty of mirrors.

Tools and Equipment: The Unsung Heroes of Mirror-Making

When it comes to the world of mirrors, the tools and equipment that go into their creation often go unnoticed. Yet, these unsung heroes play a pivotal role in ensuring the efficiency, precision, and beauty of every mirror we encounter.

From the deft hands of master mirror makers to the specialized machines that shape and polish the glass, an intricate symphony of tools and techniques come into play. These instruments are the silent partners behind the seemingly effortless reflections that adorn our homes, businesses, and public spaces.

Glass Cutting: Precision at Your Fingertips

The first step in mirror-making involves cutting the raw glass to the desired size and shape. This delicate task is entrusted to diamond-tipped glass cutters, which score the glass’s surface with surgical accuracy. Once scored, the glass is snapped along the line, creating a clean and precise edge.

Grinding and Polishing: A Smooth Finish, Every Time

Once the glass has been cut, it undergoes a process of grinding and polishing to remove any imperfections and create a smooth, reflective surface. This is where automated grinding machines step in, using coarse abrasives to remove excess glass. The machines then switch to finer abrasives to polish the glass to a mirror-like finish.

Silvering: The Magic Touch

The next crucial step is silvering, a chemical process that gives mirrors their reflective properties. This involves applying a thin layer of silver nitrate to the back of the glass. The silver reacts with the glass, forming a reflective coating.

Specialized equipment, such as electroplating machines, is used to ensure an even and durable silver coating. These machines control the thickness and uniformity of the silver layer, resulting in mirrors with optimal reflectivity.

Framing and Installation: The Finishing Touches

Once the mirror has been silvered, it needs to be framed and installed. Custom frames add an aesthetic touch, while also protecting the mirror from damage.

Mirror hanging systems come in various designs to accommodate different wall types and mounting requirements. These systems ensure the mirror is securely installed, providing a safe and visually appealing addition to any space.

The tools and equipment used in mirror-making are not just inanimate objects; they are the unsung heroes that bring mirrors to life. With their precision, efficiency, and versatility, these instruments enable the creation of stunning reflections that enhance our living and working environments.

By recognizing the importance of these tools and equipment, we not only appreciate the craftsmanship behind mirrors but also gain a deeper understanding of the intricate processes involved in their production.

Essential Tools and Equipment for Mirror Manufacturing and Installation

In the realm of mirrors, where light and reflection dance, specialized tools and equipment play a pivotal role in crafting and installing these gleaming surfaces. These instruments are the unsung heroes behind every mirror, ensuring precise cuts, flawless finishes, and secure installations.

Cutting and Shaping Tools

Precision is paramount when it comes to mirror manufacturing. Diamond-tipped circular saws slice through thick sheets of plate glass with unparalleled accuracy. Edge grinders smooth and shape the edges, creating elegant bevels or intricate designs.

Polishing and Finishing Equipment

Once cut, mirrors undergo a meticulous polishing process to achieve their lustrous finish. Automated polishing machines meticulously remove imperfections, leaving behind a blemish-free surface. Oxidation removal chemicals prepare the mirror for resilvering—the application of a reflective coating.

Resilvering Tools

For old and tarnished mirrors, resilvering breathes new life into their faded reflections. Silver nitrate solutions are applied with precision applicators, followed by a delicate silvering process that restores the mirror’s original brilliance.

Framing and Installation Materials

Mirrors don’t just appear out of thin air; they need sturdy frames and secure installation. Wooden frames in various styles and finishes enhance the mirror’s aesthetic appeal. Mounting brackets, screws, and adhesives ensure the mirror remains safely and securely in place.

Safety First

Mirror manufacturing and installation demand unwavering safety measures. Safety gloves protect hands from sharp edges, while goggles shield eyes from flying debris. Resilvering processes require proper ventilation and protective clothing to minimize exposure to chemicals.

These tools and equipment are more than just inanimate objects; they are the lifeblood of the mirror industry, enabling the creation of breathtaking reflections that grace homes, businesses, and public spaces alike.

The Entities Behind the Mirror: A Journey into the Mirrorverse

Mirrors, the enigmatic objects that reflect our faces, have fascinated and played a pivotal role in our lives since time immemorial. From ancient polished obsidian to modern high-tech reflective surfaces, the journey of the mirror is a testament to human creativity and innovation. Today, the mirror industry is a diverse and dynamic ecosystem, encompassing a myriad of entities that collectively contribute to the creation, maintenance, and versatility of mirrors.

Primary Entities: Architects of the Mirrorverse

Mirror Manufacturers:

The foundation of the mirrorverse rests upon the master craftsmen and women who craft these reflective wonders. These companies employ state-of-the-art techniques to create a symphony of mirrors, ranging from sleek and modern to ornate and vintage. Each mirror is a masterpiece of precision, tailored to meet the diverse needs of various applications, from vanity mirrors to architectural marvels. Their meticulous attention to detail ensures that every mirror reflects not only our image but also the highest standards of craftsmanship.

Mirror Resilvering Services:

When the silvering of a mirror fades, obscuring its pristine surface, expert mirror resilvering services step onto the stage. These skilled technicians breathe new life into aged mirrors, employing meticulous techniques to restore their former glory. The process of resilvering involves carefully removing the old, tarnished silver layer and applying a fresh, reflective coating. The result is a mirror that once again captures the world with pristine clarity, its youthful glow restored.

Secondary Entities: The Unsung Heroes of the Mirror Industry

Glass Companies:

The backbone of mirror production lies in the pristine glass that serves as its canvas. Glass companies are the unsung heroes of the mirror industry, providing the high-quality plate glass that forms the foundation of every mirror. They ensure that the glass is free from imperfections, ensuring that the mirrors they produce offer undistorted reflections. Their expertise in crafting flawless glass is a testament to their dedication to excellence, elevating the mirror to an art form.

Chemicals and Materials:

The realm of chemistry plays a vital role in the mirror-making process. Specialized chemicals are meticulously formulated to create the silvering that gives mirrors their reflective properties. These chemicals interact with the glass surface, forming a durable and highly reflective coating. The precise balance of these chemicals is crucial, influencing the mirror’s clarity and longevity.

Tools and Equipment:

From diamond-tipped cutters to precise measuring devices, the mirror industry relies on a sophisticated arsenal of tools and equipment. These tools empower mirror manufacturers and resilvering technicians to work with the utmost precision and efficiency. State-of-the-art machinery ensures that each mirror is cut, shaped, and finished to perfection, while specialized equipment streamlines the resilvering process. These tools are the invisible hands that orchestrate the creation of mirrors that meet the highest standards of quality and craftsmanship.

The mirrorverse is a tapestry woven by a constellation of entities, each contributing their unique expertise to the creation and maintenance of mirrors. From the artistry of mirror manufacturers to the precision of resilvering services, from the pristine glass provided by glass companies to the precision tools and chemicals used in the process, the mirror industry is a testament to human ingenuity. These entities work in harmony, their interconnectedness reflecting the complex and captivating nature of the mirror itself. Together, they ensure that mirrors continue to serve as gateways to self-reflection, objects of beauty, and indispensable tools in our everyday lives.